Architecture & 3D Printing

Imagine a world where buildings are printed, not built. Sounds like sci-fi, right? Welcome to the future, where 3D printing concrete structures is transforming how we design and construct our surroundings. This advanced construction technique blends digital precision with the versatility of concrete, offering new possibilities for architecture.

Detailing in 3D printed concrete is like having a magic wand for creating intricate designs that were once impossible. Picture icing a cake with the precision of a master chef. 3D printing builds structures layer by layer, allowing exact control over shape and texture, enabling the creation of unique surface patterns and fine details. Customization is limitless, allowing for bespoke designs that make cookie-cutter buildings a thing of the past. Additionally, utilities like electrical conduits and plumbing can be seamlessly integrated into the walls, reducing post-construction headaches.

CONSTRUCTING COMPLEX ELEMENTS

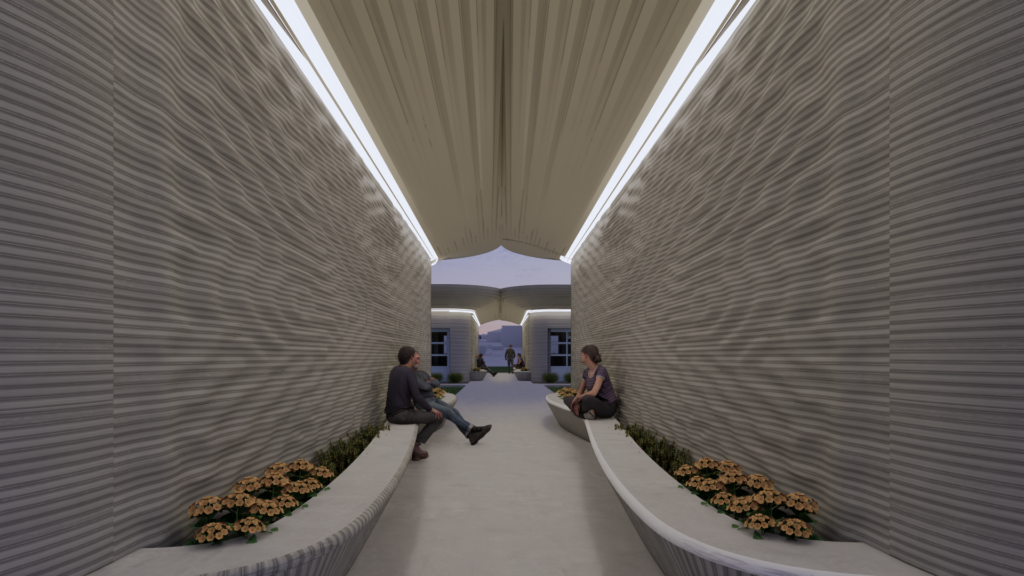

One of the most exciting aspects of 3D printed concrete is the ability to print complex parametric geometry. This means architects can design and construct highly intricate and mathematically defined shapes that would be incredibly difficult, time-consuming, and expensive to achieve with traditional methods. Imagine structures that mimic the fluidity of nature or intricate lattice patterns that combine both beauty and functionality.

Concrete MIX & CURING

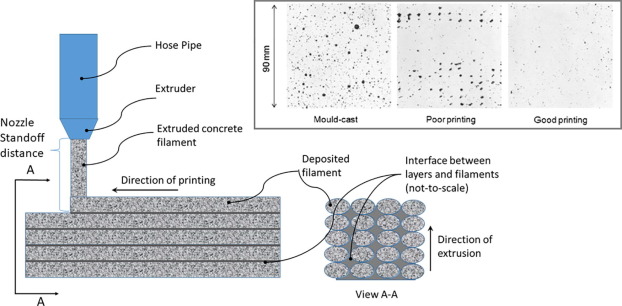

The process of constructing a 3D printed concrete structure is straightforward. It starts with creating a detailed digital model using CAD software, which serves as the blueprint. The construction site is prepared, setting up a 3D printer that extrudes concrete. The concrete mix, prepared to specific criteria, is pumped into the printer, which lays it down in precise layers, building the structure from the ground up. Depending on the size, this can take a few hours to several days. After printing, the concrete needs time to cure and gain strength, followed by any necessary finishing touches.

Creating the perfect concrete mix for 3D printing is crucial. The mix must be flowable enough to be extruded smoothly but stiff enough to hold its shape once printed. It needs a suitable set time to ensure each layer adheres properly to the previous one without slumping. The mix must achieve the necessary strength and durability to meet structural requirements, involving the right proportions of cement, aggregates, and additives. Consistency in the mix ensures uniformity in the printed layers and prevents defects.

Image From: Mix Suitable for Concrete 3D Printing: A Review

Paper Written by M.A. Khan

source: https://www.sciencedirect.com/science/article/abs/pii/S2214785320326328

Advantages of 3D Printing

3D printing concrete structures offers several advantages in terms of efficiency and cost. Automation significantly reduces the need for manual labor, leading to lower costs and fewer on-site accidents. The speed of construction is dramatically shortened, with structures that traditionally take weeks or months being completed in days. The precision of 3D printing minimizes material waste, translating to cost savings and a smaller environmental footprint. This method also allows for greater architectural innovation and differentiation, as complex and customized designs come without additional costs. On-demand construction is particularly beneficial for emergency housing or remote locations where traditional construction resources are scarce.

3D printing concrete structures represents a transformative advancement in architectural construction techniques. By merging digital precision with the versatility of concrete, this method offers new possibilities for design, efficiency, and sustainability. As the technology evolves, it promises to make construction faster, more cost-effective, and more environmentally friendly. So, next time you see a futuristic building, remember: it might just have been printed, not built.

Location:

Austin, TXConstruction Duration:

2021-2022Construction Type:

Tilt WallDate:

June 3, 2024